INDUSTRIAL

REVERSE OSMOSIS

WATER TREATMENT SYSTEMS

What is Reverse Osmosis?

Reverse osmosis (RO) is a very effective water treatment process that removes impurities utilising a semi-permeable membrane.

RO is a simple, safe and cost-effective process to remove up to 99.8% of all waterborne contaminants from a water stream including bacteria, pyrogens, dissolved solids and organics.

Our industrial RO water treatment systems are designed in partnership with Ecosoft, a leading international water filtration systems provider.

Reverse osmosis (RO) is a very effective water treatment process that removes impurities utilising a semi-permeable membrane.

RO is a simple, safe and cost-effective process to remove up to 90% of all waterborne contaminants from a water stream including bacteria, pyrogens, dissolves solids and organics.

How does an RO system work?

Osmosis is the natural process by which a fluid such as water passes across or through a semi-permeable membrane from an area of high to lower concentration. With RO water treatment, the natural process is reversed so that the water flows in the opposite direction which results in highly purified water.

With an RO system, a pump generates enough pressure to force the feed water through the membrane against its natural flow, which ensures that the water molecules pass to a purified water tank where the contaminants are blocked and discharged as a separate reject water for disposal elsewhere or for recycling back into the RO system for treatment again.

Applications

RO water treatment systems are used effectively in a wide variety of industries and commercial applications such as:

CAR WASH

High-quality rinse water

for a perfect result

BOILER FEED

Optimal treatment of boiler water for removal of impurities in feedwater

DISTILLERY

High quality, pure water used

for food & beverage production

BREWERY

Correct water treatment

enhances the taste of beer

DAIRY & MEAT

PROCESSING

High quality, pure water

used for food production

HEALTHCARE &

LABORATORIES

De-mineralized water of high purity with low content of organic substances & microorganisms

POWER

GENERATORS

Optimal water treatment

for high pressure steam boilers

DATA

CENTRES

Water treatment technologies

for reliable

operation in data centres

RO as a process technology can also be incorporated with ultra filtration and continuous electro-deionisation where applicable.

Benefits of RO Water Treatment Systems

- Has a compact footprint

- Has lower operating cost and a more enhanced energy efficiency due to ambient temperatures

- Has a significant safety benefit as no hazardous chemicals are required in the process - no transport - no storage of chemicals

- Ensures continuous operation that requires no downtime for regeneration

- Can be used to treat all types of feedwater

- Can be integrated with other water treatment technologies and retrofitted to existing systems

- Maintains downstream equipment from fouling, scaling and damage

- Ensures significant reduction in contaminants and total dissolved solids (TDS)

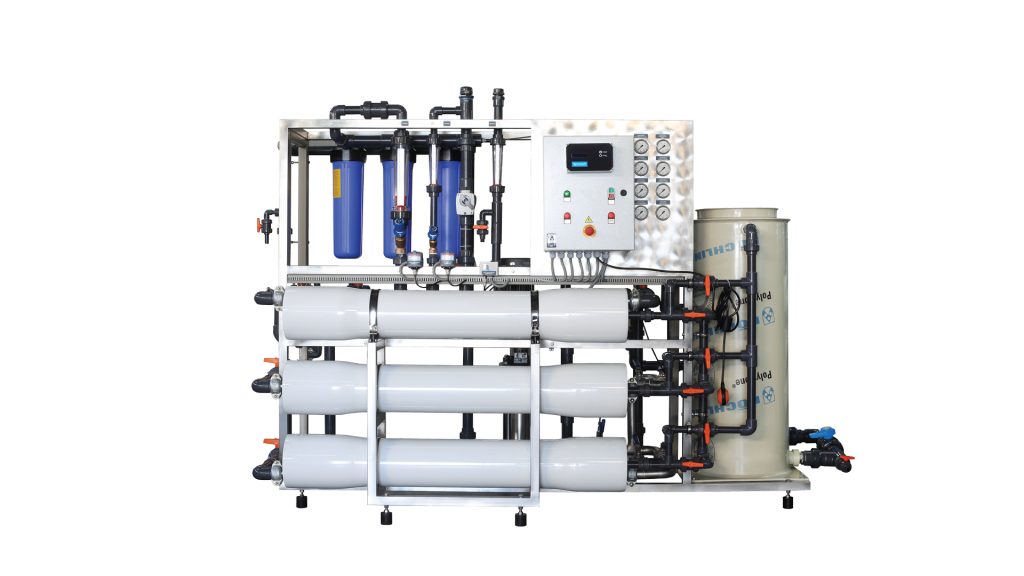

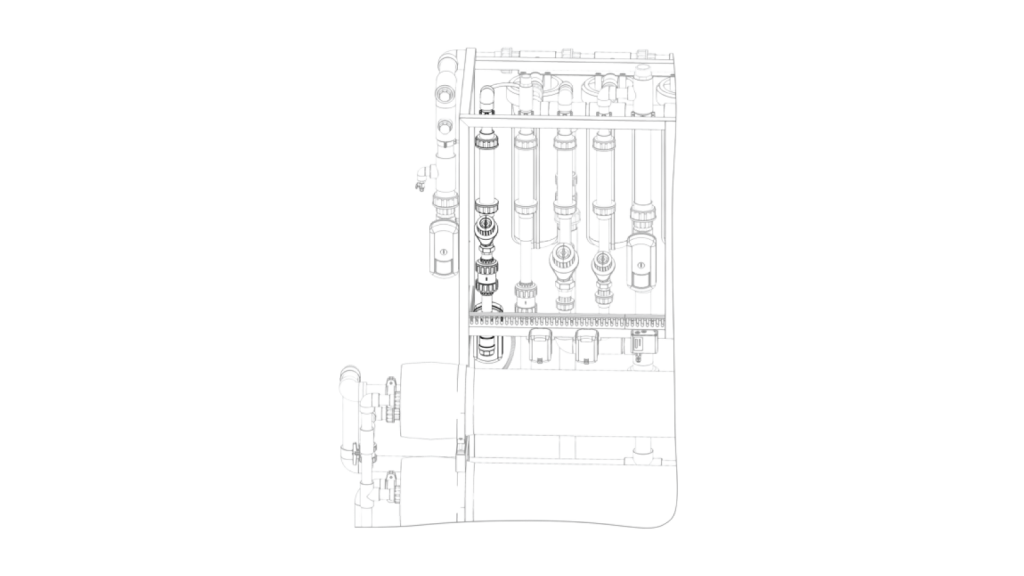

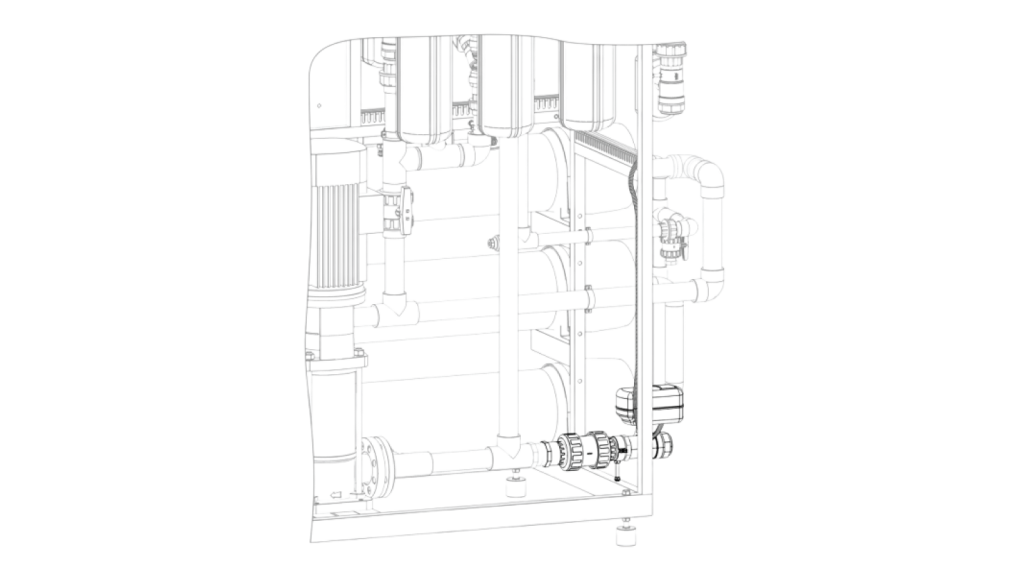

Our RO water treatment products

Our range of 8” membrane industrial RO water treatment systems are designed for reliable and durable operation. We have two product offerings the INOX and Standard, engineered to treat water containing dissolved solids up to 4500 ppm. Systems consist of 2 to 48 8” RO membranes psc, delivering high-quality purified water from 2 m3/h up to 58 m3/h.

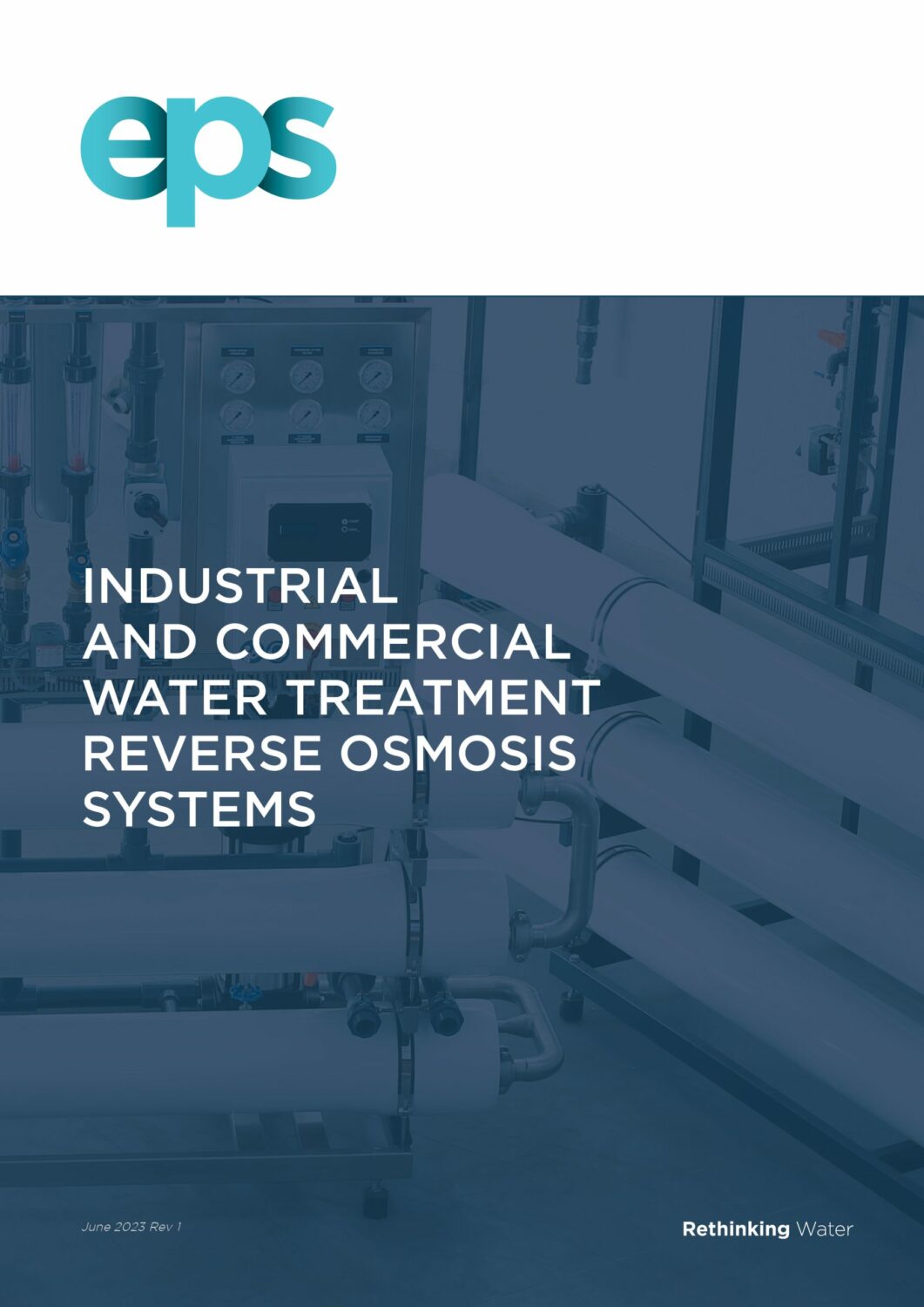

8" INOX

- AISI 304 stainless-steel frame and AISI 316 stainless-steel high-pressure line

- Resilient to corrosion and extra long-lasting operation

- System capacity 2 m3/h-12 m3/h

- Feed water TDS up to 4500 ppm

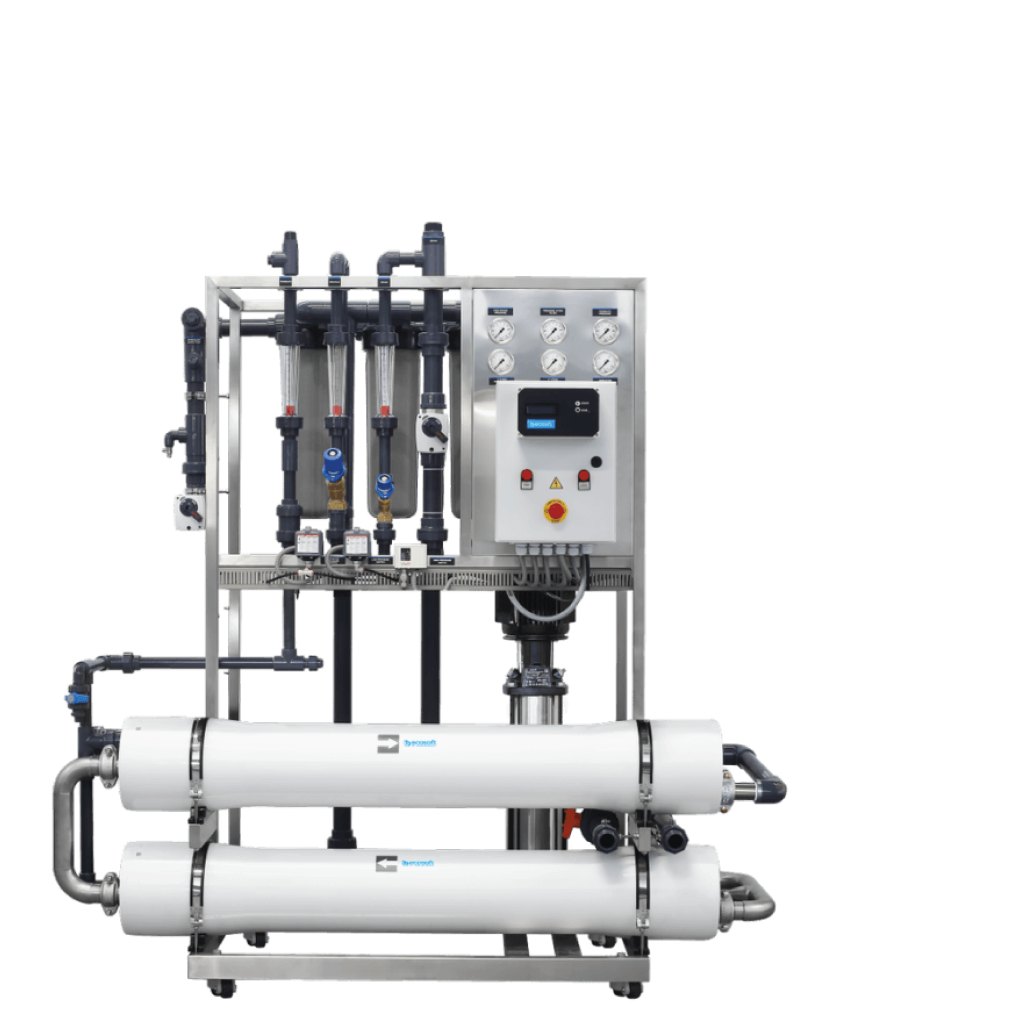

8" Standard

- Powder-coated frame

- Cost-effective

- System capacity 2 m3/h- 56 m3/h

- Feed water TDS up to 3000 ppm

Key Components

- Grundfos pressure pump (high energy efficiency, low noise and vibration)

- RO membrane vessels 8040/300psi

- Sediment pre-filter BB 4.5x20/ 5 mic or stainless steel multi filter housing

- Danfoss or Praher motorized valves

- Honeywell or Praher regulating valves

- Piping, valves, instrumentation, frame

- Permeate flushing port

- TDS blending line port

Selection of RO membranes

Ecosoft ELP-8040-400

Capacity 42 m3/day

Ecosoft ELP-8040-400

Membrane elements ELP 8040-400 are suitable for the treatment of brackish water in low pressure systems. The large active surface area combined with high rejection rates allows the utilisation of these membranes in variable pressure and flow conditions without a deterioration in the permeate quality.

- Good water flow

- High rejection provides good water quality

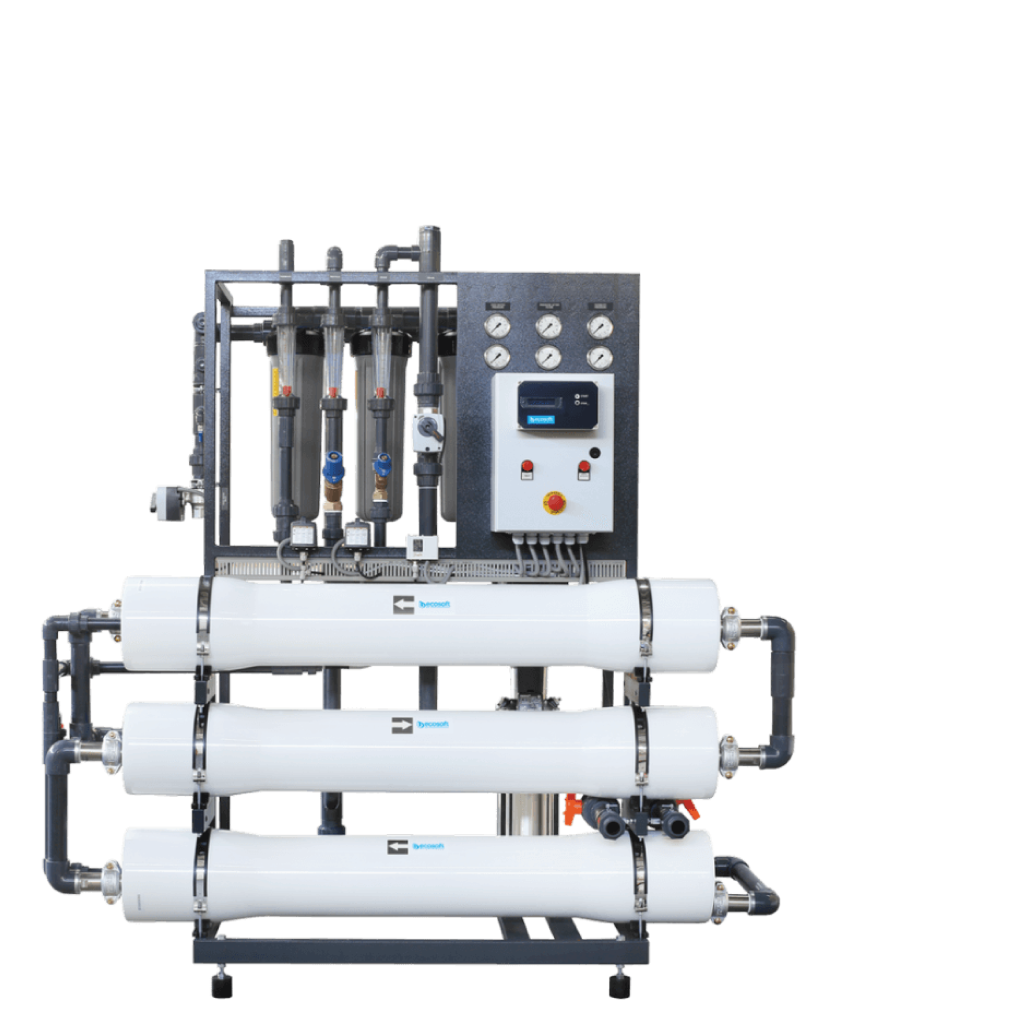

DuPont-Filmtec XLE440

Capacity 53 m3/day

DuPont-Filmtec XLE440

Dow Filmtec™ XLE-440 membrane is a high-performance reverse osmosis element with a low energy consumption. Suitable for the treatment of water with medium level of mineralization. It provides higher quality water at lower operating costs. The Dow Filmtec™ XLE-440 membrane element operates at lower pressure for reverse osmosis, and thus reducing energy consumption.

- High water flow

- High salt rejection

- Good water quality at very low applied pressure

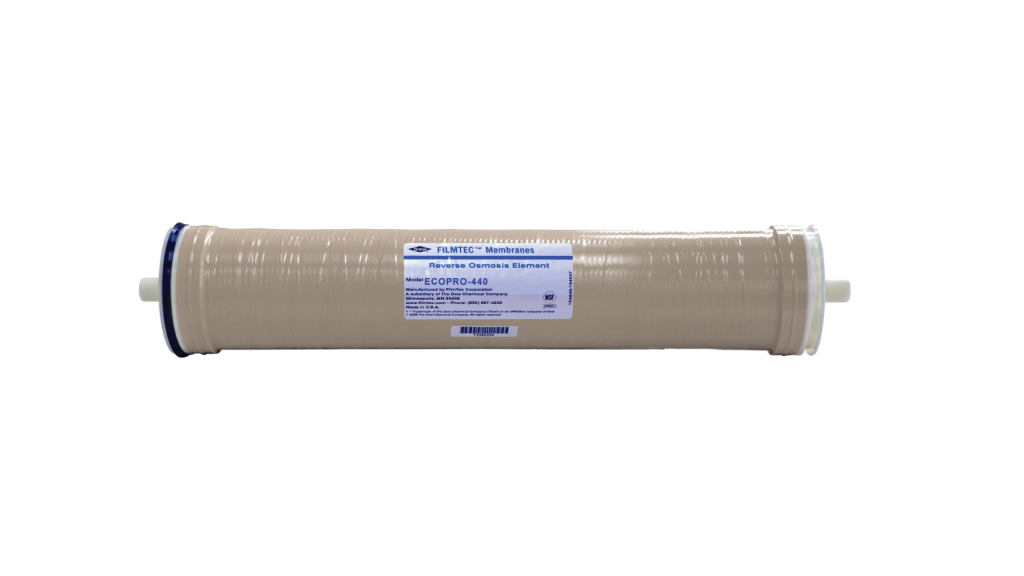

DuPont-Filmtec ECOPRO-440

Capacity 48 m3/day

DuPont-Filmtec ECOPRO-440

Dow Filmtec™ ECO PRO-440 is a high-performance reverse osmosis element with low energy consumption. Suitablefor purification of water with medium level of mineralization. It provides highquality water at low operating costs. The Dow Filmtec™ ECO PRO-440 membrane element operates at pressure minimal for reverse osmosis, by this reducing energy consumption.

- Operates at a low applied pressure

- Delivers excellent silica, boron, nitrate, total organic carbon and ammonium rejection

Optional Extras

We offer optional extras to complement and enhancing the functionality and performance of our industrial RO systems.

CIP Station

CIP Station

Clean-in-place technique allows cleaning and sanitizing RO membranes without having to move the system.

Over time in operation RO membranes might decline in performance due to the accumulation of deposits on the surface. Mineral scale, colloidal particles, organic compounds are the common causes of membrane fouling.

When RO system capacity drops by at least 10 percent membrane cleaning should be performed using CIP systems. Our factory assembled, tested and field-ready cleaning skids offer a convenient and economical way to maximize RO investment.

CIPSEP616

CIP for 8″ membranes RO systems MO6, MO9, MO12, MO16

Includes

- Polymer storage tank for cleaning solution - 350 L

- Grundfos pump CRN 10-6, 2,3 kW, 3 × 400 V

- Sediment filter 4.5x20 polypropylene cartridge (3 pcs)

- Electrical panel

- Pressure gauge (1 set)

- PVC piping and valves

- Powder coated stainless steel frame

CIPSEP

CIP for 8″ membrane RO systems MO2, MO3, MO4

Includes

- Polymer storage tank for cleaning solution - 100 L

- Grundfos pump CM 3-4, 2,2 kW, 380 V

- Sediment filter 4.5x20 with polypropylene cartridge

- Electrical panel

- Pressure gauge-1 pcs, temperature & pressure gauge -1 pcs

- PVC piping and valves

- Powder coated stainless steel frame

Chemical Dosing Pump Kits

Chemical dosing pump kits

Dosing water treatment chemicals for reverse osmosis, heating/cooling circuits, boiler feed water, process water, CIP systems, water remineralization, and other additives.

components

- Dosing Pump

- Suction valve with foot filter and level probe

- Injection valve

- Pack of hoses

- Chemical tank with mounting bracket

- 500 mL graduated cylinder

- Water meter with pulse output

- Suitable for high flow applications

- High wear resistance in demanding conditions

- High precision in a broad flow control range (logarithmic control scale)

Benefits

- Accuracy and ease of setting

- Working pressure up to 10 bar

- High flow rate up to 6 L/h

- Low noise level

|

Product

|

Description

|

Dosing Pump Max Capacity

|

Chemical storage tank / pulse meter (if included)

|

|---|---|---|---|

|

D100660

|

EMEC FACO basic dosing pump set (no meter connectivity)

|

0.6 L/h @ up to 10 bar

|

60 L / —

|

|

99135150-60BASIC

|

Grundfos DDC 6—10 basic dosing pump set without pulse meter

|

6.0 L/h @ up to 10 bar

|

60 L / —

|

|

99135150-120BASIC

|

Grundfos DDC 6—10 basic dosing pump set without pulse meter

|

6.0 L/h @ up to 10 bar

|

130 L / —

|

|

99135150-120-40BASIC

|

Grundfos DDC 6—10 basic dosing pump set with pulse meter

|

6.0 L/h @ up to 10 bar

|

130 L / DN 40

|

|

99135150-60-25BASIC

|

Grundfos DDC 6—10 basic dosing pump set with pulse meter

|

6.0 L/h @ up to 10 bar

|

60 L / DN 25

|

Raw Water Blending Assembly

Raw water blending assembly

The product is used to amend the mineral composition of permeate or increase the RO system capacity.

features

- The raw water blending assembly has a separate inlet port for blending water from any source to the purified water.

- The balancing valve is used for regulating and sustaining the required flow rate of raw water.

- The motorized valve opens during service and shuts off during standby or downtime.

components

- Motorized valve

- PVC check valve

- Rotameter

- PVC pipeline, mounting clamps

- Installation and connection instructions

*EPS industrial RO systems have built-in flush ports for the flushing assembly connection

|

Code

|

For systems

|

Maximum flow rate

|

Connection port size

|

|---|---|---|---|

|

IMO1234

|

MO2TP5, MO3TP5, MO4TP5, MO2TI5, MO3TI5, MO4TI5

|

2,5 m3/h

|

DN15

|

|

IMO69

|

MO6TP5, MO9TP5, MO6TI5, MO9TI5

|

6 m3/h

|

DN25

|

|

IMO1224

|

MO12TP5, MO16TP5, MO24TP5, MO12TI5

|

16 m3/h

|

DN40

|

|

IMO3048

|

MO36TP5, MO48TP5

|

25 m3/h

|

DN50

|

Permeate Flushing Assembly

Permeate flushing assembly

This product fits an already operating RO systems, using a few basic tools. The flushing assembly has a large flow capacity for efficient membrane flushing. Operating time and frequency are set up in the controller settings.

used in the following cases

- Insufficient supply water flow for normal membrane flush

- Longer membrane service life before CIP is required, especially on difficult feed water analysis

- Supply water treatment process can be sized to a smaller flow capacity. No peak flow demand dur-ing membrane flush

- Industrial reverse osmosis systems have built-in flush ports for the flushing assembly connection

components

- Motorized valve

- PVC piping assembly with PVC check valve

- Pipe clamp and fasteners

- Installation and connection instructions

|

Code

|

For systems

|

recommended flow rate

|

Connection port size

|

|---|---|---|---|

|

PMO1234

|

MO2TP5, MO3TP5, MO4TP5, MO2TI5, MO3TI5, MO4TI5

|

8 m3/h

|

DN40

|

|

PMO69

|

MO6TP5, MO9TP5, MO6TI5, MO9TI5

|

15 m3/h

|

DN50

|

|

PMO1224

|

MO12TP5, MO16TP5, MO24TP5, MO12TI5

|

30 m3/h

|

DN80

|

|

PMO3048

|

MO36TP5, MO48TP5

|

50 m3/h

|

DN100

|

Break Tank

DuPont-Filmtec XLE440

Dow Filmtec™ XLE-440 membrane is a high-performance reverse osmosis element with a low energy consumption. Suitable for the treatment of water with medium level of mineralization. It provides higher quality water at lower operating costs. The Dow Filmtec™ XLE-440 membrane element operates at lower pressure for reverse osmosis, and thus reducing energy consumption.

- High water flow

- High salt rejection

- Good water quality at very low applied pressure