Distance To Site

1000

KM

MAR 2019

PROJECT START DATE

success criteria achieved

1

%

temperature

0

°C

Commercial

British Antarctic Survey (BAS)

Sludge Treatment/Mechanical DfMA Package

The station operates all year, with over 100 scientists, meteorologists, engineers and support staff present in the summer months, reducing to a skeleton staff of only 22 in winter. The environment is extreme, with highly variable weather conditions throughout the year and winter temperatures frequently at -20°C or lower.

BAS went to the market seeking a solution at Rothera that could meet capacity demand with minimal interruption to treatment. EPS were appointed following a tender process co-ordinated for BAS by Crown Commercial Services.

The project was named DfMA Project of the Year at the 2020 Water Industry Awards.

The EPS solution proposed a Salsnes Filter primary belt filter system upstream of the existing SAF plant. It was found to be the most economically advantageous solution to meet the key project requirements.

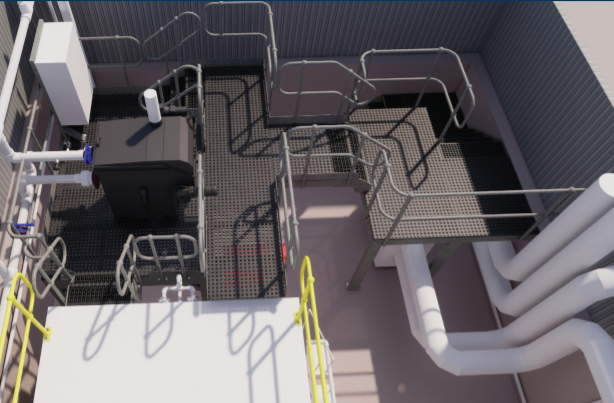

EPS co-ordinated a collaborative and immersive design ‘sprint’ alongside BAS and Salsnes Filter teams, to create an integrated design within a short timeframe to keep the project on programme. A federated digital model was produced and this was reviewed remotely by relevant stakeholders using cloud hosting and remote meeting tools.

The entire filter/platform/access assembly was fully pre-assembled at the EPS factory, and was then factory inspected and tested in the presence of the BAS team including those who would supervise its installation at Rothera.

EPS and Salsnes worked together to provide a remote support role for BAS throughout the installation and commissioning process.

The innovation on this project was the means by which it was developed and delivered to meet the specific demands of this challenging solution.

From the outset, EPS chose to use our digital design platform and an off-site delivery strategy under a Design for Manufacture & Assembly (DFMA) initiative to address specific challenges and de-risk the overall project.

The Rothera wastewater treatment building, existing assets and services within it, were surveyed in detail and a 3D model developed as a highly-reliable basis for design. As well as providing the basis for fabrication, the model of the solution was used for client engagement/approval, proof of modular installation, clash detection, interface planning and as an installation planning tool.

Digital/DFMA has a key role to play in the delivery of remote assets and is equally beneficial in the delivery of smaller scale assets, especially where there are disproportionate risk factors involved. By assessing and quantifying risks at each stage of the project using ‘what if’ scenarios and a virtual asset model, decision making and planning outcomes were significantly enhanced.

The Rothera project highlights the importance of the solution in maintaining treatment standards in such a pristine and sensitive environment, the dramatically increased risk arising from this remote and hostile site location and the communication and co-ordination challenges created from collaborative teams operating in different parts of the world.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |