Project Cost

£

1

M

NOV 2017

PROJECT START DATE

CONSTRUCTION PERIOD

1

MONTHS

CAPACITY

100

MLD

The construction of the UK’s second wastewater treatment plant using the Nereda® process reached a major milestone on Friday 22nd June 2018 with the first discharge to river from the new process stream.

Utility

Anglian Water/@oneAlliance

Nereda®

Great Dunmow Water Recycling Centre (WRC) is located a few kilometres to the east of Stansted Airport in Essex and serves a population of approximately 10,000 people. Due to ongoing capacity limitations and operational issues in the existing works, Anglian Water elected to construct a new treatment plant on the site to serve the current and future needs of Great Dunmow and its catchment. A wide range of site constraints led to the selection of a novel treatment technology and the use of cutting-edge design and construction practices to achieve the required project outcomes.

The project has been delivered by Anglian Water’s capital delivery partners in the @One Alliance. At an early stage, space constraints dictated that use of a conventional activated sludge process was not feasible and, following early engagement with EPS and Royal Haskoning DHV, Nereda® was selected as the preferred solution.

Nereda® is an aerobic granular sludge process, originally developed at the University of Delft in Holland and now owned and licensed by Royal HaskoningDHV. The technology is well proven with more than fifty projects worldwide and achieves high standards of nutrient removal on a significantly smaller footprint than conventional processes, whilst also delivering operational cost benefits including energy and chemical savings.

In the usual treatment process, flocs of sludge are suspended in the water. It takes time for these flocs to settle in the treated wastewater, and a specific secondary settlement stage is needed.

What makes the Nereda® process so special is the aerobic granular biomass. Owing to their composition, the granules have an aerobic outer shell which is rich in oxygen and a anoxic/anaerobic core that is low in oxygen. This means that different treatment conditions

can be found within a single granule. In a normal treatment plant, the high-oxygen and low-oxygen processes take place in different parts of the overall process. Nereda® granules, however, can nitrify and de-nitrify simultaneously, as well as removing phosphorus from the wastewater.

Nereda® granules settle much faster, and can do so in the same tank in which the treatment process takes place, eliminating the need for clarifiers.

The technology was first discovered by the Delft University of Technology in the Netherlands and developed in a unique public/ private partnership between the University, the Dutch Foundation for Applied Water Research (STOWA), the Dutch Water Boards and Royal HaskoningDHV. After 20 years of research and development this innovative biological solution is now proving itself to be a leap forward in wastewater treatment technology.

The new works was designed to enable Great Dunmow WRC to meet statutory discharge consents including a reduced BOD consent of 10mg/l, a reduced ammonia consent of 3mg/l and a new total P consent of 2mg/l, along with an increased influent peak flow of 161 litre/sec and an FFT of 57 litre/sec excluding returns. This design is intended to provide the plant with a future growth design horizon of at least 2031.

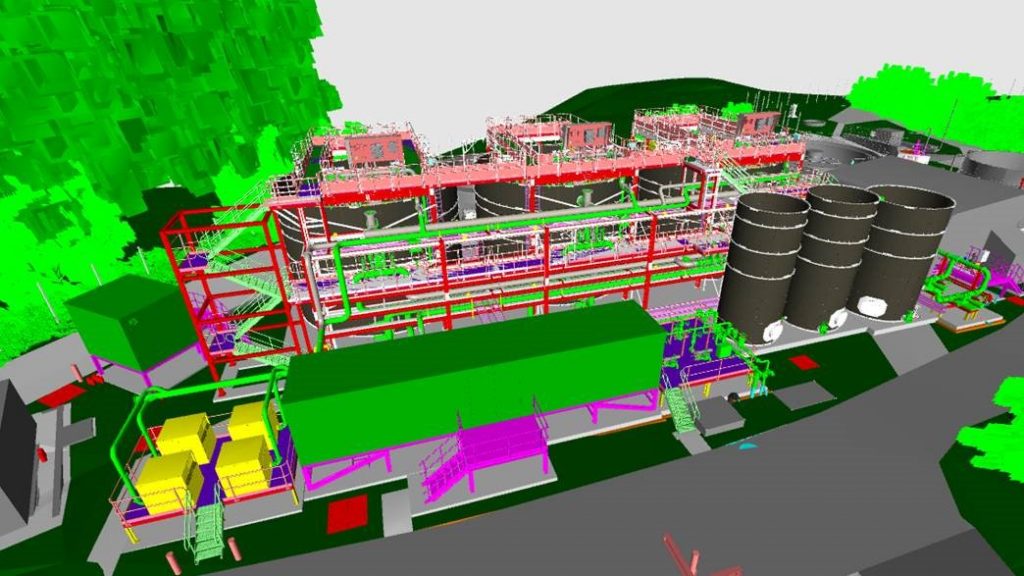

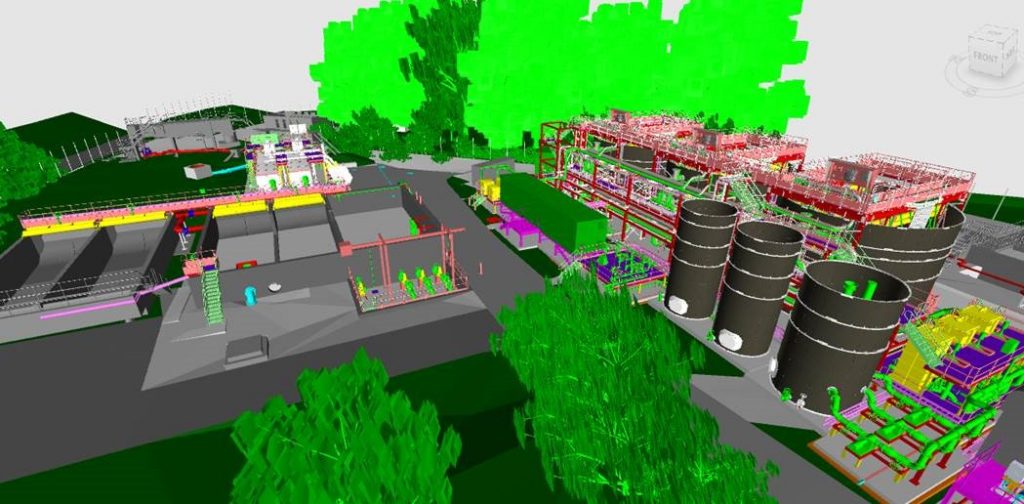

In the final solution, the majority of the old MBBR works was replaced. The assets retained included the main inlet pumping station, the old stormwater holding tanks, the thickened sludge holding tank, and the final effluent sampling chamber, flume and outfall. In addition, the old blower house was re-purposed to house the new sludge thickening plant.

A tapping on the feed to the old inlet works now diverts flow to a large twin-stream packaged inlet works structure. This comprises of two Huber RO9 combined screening, grit removal and FOG removal units, sized for duty/standby operation. Access and pipework for the inlet works has been delivered in pre-assembled integrated steel structures which integrated seamlessly around the Huber units.

Flow from the new inlet works passes to the Nereda® influent buffer tank. An overflow from the buffer feeds two new stormwater holding tanks and the two original storm tanks in a daisy-chain arrangement. Stormwater tipping buckets have been installed to clean these tanks following each use. Flygt forward feed pumps transfer the raw wastewater from the buffer tank to the Nereda® reactors and Flygt jet mixing pumps are also provided to maintain adequate mixing within the buffer tank.

The Nereda® reactors comprise of 3 (No.) glass-coated steel tanks of 570m3 volume each, containing diffusers and other internal equipment to suit the RHDHV design. The Nereda® process is controlled by an Aquasuite® controller which interfaces with the PLC within the new main motor control centre. Air to the process is supplied by four Aerzen process blowers are mounted onto a pre- assembled elevated skid, and tertiary solids removal is achieved using three Fuzzy FilterTM compressible fibrous media up-flow filter units supplied by Bosman Watermanagement.

Sludge is collected in two steel buffer tanks and is transferred using a pre-assembled elevated skid with Borger rotary lobe type sludge pumps. A new Huber S-Disc thickener unit has been installed into the old blower house, along with polymer dosing equipment and other ancillaries.

Additional upgrades have been carried out to the treated effluent outfall, the washwater pumping station and the site-wide washwater network.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |